|

|

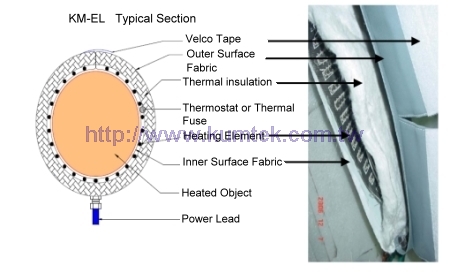

KM-EL Flexible Heating Jackets

are composed of heating element, thermostat, thermocouple, high temperature fabrics, and Insulation blanket (as an integral part by sewing) and power cable/connector for connecting to electric controller.

|

|

| BENEFITS AND FEATURES OF KM-EL: |

- By integrating heating and thermal insulation into one part, KM-EL are fabricated to fit contour of heated objects with Velcro or fastening belts/D-rings for easy installation

- Good thermal insulation and electric energy efficiency, low surface temperature, and uniform heat distribution.

- All materials used are either non-combustible or, at least, flame-resistant,

High temperature capability to 1000°C

- Selection from Comprehensive materials of heating element, fabrics, Insulation blanket, sewing thread for most appropriate Combination of KM-EL

- Clean room compatible

- Heating pad can be supplied with moisture/splash proof with 1.2mm thick only.

|

| Built-in security devices and Power |

| Power |

100 to 240 Vac |

Fuction |

Thermostat

|

80 to 160°C (5°C per increment), 200°C, 550°C, 710°C |

Open (disconnect) the power circuit at preset temperature, to eliminate over heating. Close (reconnect) the circuit when temperature drop. |

| Thermal Fuse |

220°C, 270°C |

Will disconnect the power circuit permanently

At pre-set temperature. |

| LED Power Indicator |

Green or Orange colored |

Blinking for normal. Off for failure |

|

| KM-EL Typical Cross Section |

|

| Materials Used |

|

| Materials selected based on the operation temperature and other requirements (ie: clean room) |

| Part Name |

Material |

Temp. Resistance |

Features |

Heating Element

|

Ni-Cr alloy |

|

Select the appropriate material from world leading manufacturer for required durability and Resistance (from 0.8Ω/m to 4000Ω/m),

By selection the element Resistance and winding pitch, the wattage of KM-EL can be from 0.1W/cm2 to 0.8W/ cm2 |

| Outer Braided Insulation for Heating element |

Special formulated

Glass fiber |

650°C |

Contain no material (ie. Silicone) that will de-grade at high temperature |

KM1000 fiber |

900°C |

KM1200 fiber |

1200°C |

|

| Material |

Temp. °C |

Features |

Applications |

Inner

Layer |

Outer

Layer |

Insulation |

| 100% PTFE Film |

290 |

Flame Resistance, Class 10 Cleanroom Standard, No smoke/odor at high temperature, 0.08mmthick, soft , weathering and UV resistance, non-stick surface, water Oil resistance, easy for cleaning, excellent chemical resistance |

◎ |

◎ |

X |

PTFE coated glassfiber cloth

|

290 |

Flame Resistance, Class 1 or Class 10 Cleanroom Standard, No smoke/odor at high temperature, soft, , weathering and UV resistance, non-stick surface, water & Oil resistance, easy for cleaning, chemical resistance |

◎ |

◎ |

X |

| Aluminized glassfiber cloth |

200 |

Flame Resistance, Class 1 Cleanroom Standard, superior surface aluminization (no de-lamination, smooth surface) non-stick surface, water & Oil resistance, easy for cleaning, |

X |

◎ |

X |

| KM1200 Cloth |

1200 |

Non-combustible, Retain required strength , flexibility , insulation at 1200 °C |

◎ |

△ |

X |

| KM700 Cloth |

650 |

Non-combustible, Retain required strength , flexibility , insulation at 650 °C |

◎ |

△ |

X |

| KM600 Blanket |

500 |

Non-combustible, good thermal insulation, much less off smoke and smell than other brands. |

X |

X |

◎ |

| KM1000 Blanket |

900 |

X |

X |

◎ |

|

| |

|

|

|