KM600-CR Insulation for Clean Room

By using non-asbestos high temperature fabric as inner

and outer layers and insulation blanket (alumina-silicate

fiber blanket or needled fiberglass felt) as medium layer.

KM600-CR is ideal substitute to conventional insulation by

fiberglass, rockwool, calcium silicate or Perlite insulation

with aluminum or stainless covering and has been proven

suitable for clean room applications by numerous cases.

KM600-CR will provide excellent insulation value, help to

reduce the energy loss, minimize the burning injuries.

|

|

| Layers Construction |

Materials |

Outer layer |

Insulation |

Inner layer |

Velcro Tape |

Material ID |

IN-AL#4-43L/M

Aluminized

Fiberglass Cloth

|

Alumina-Silicate

fiber blanket |

INFLUO#4-56P/P

PTFE coated

Fiberglass cloth

|

Flame retarded PVC

or Nomex |

Thick (mm) |

0.4 |

6 to 50 |

0.4 |

-- |

Flame Resistance |

CNS 10285, Grade-1

FED STD191/5903.3:

Flame out-1 sec.

Afterglow- 1 sec.

Char Length-1"

|

CNS 6532 Grade-1

Non-combustible |

CNS 10285, Grade-1,

FM4910, UL94 VO

(PTFE) |

|

Color |

Silver/white

|

White |

Gray/dark brown |

|

Temperature resistance °C |

204/500

(base material) |

1000+ |

287/500(Base material) |

180(PVC)/

240(Nomex) |

| Clean Room class |

Per IES-RP-CC003.2 method, by Helmke Drum Rotating Test

Particles >/= 0.3μm: 4 count/pc, >/=0.5μm: 1 count/pc, >/=1μm: 0 count/pc ,meet FED. STD. 209E Class 1 and ISO-14644-1 ISO 1 |

|

Nomex is the trademark of DuPont

Benefits

- EASY TO INSTALL, REMOVABLE AND RE-USABLE:

No special techniques/tools required for installation. The jacket is made To conform to intricated shapes and CAN BE REMOVED/REINSTALLED MULTIPLE TIMES EVEN BY THE END USERS.

- NO POLLUTION TO CLEAN-ROOM ENVIRONMENT !

All KM600 jackets are thoroughly cleaned before being brought into clean Room. The surface are smooth and free from any particle and dust.

NO POLLUTION THROUGHOUT THE LIFE OF THE JACKETING FROM INSTALLATION, INTERNAL MAINTENANCES (REMOVED AND REINSTALLED) TO REPLACEMENT.

- EXCELLENT INSULATION EFFECT TO 280 °C:

Thermal conductivity of the insulation (medium layer) is around, 0.06W/m.k. At 200°C only with very low specific heat (low heat storage). Low outer face temperature and energy conservation can be achieved.

|

|

Operation Temp. |

KM600-CR Surface Temp. |

KM600-CR Surface Heat Loss W/m2 |

170°C |

45°C |

179 |

180°C |

47°C |

194 |

190°C |

49°C |

208 |

200°C |

50°C |

223 |

|

|

| Assumption of above estimation: 25mmt insulation at 25°C ambient temp., no. wind |

|

| KM600-CR Installation |

|

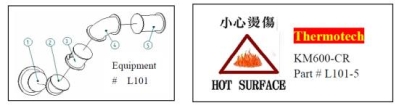

| All KM600-CR jackets are fabricated to the sizes of the ducts and or equipments with marking as per drawing as illustrated in below. |

|

|

|

- Installation of KM600-CR is best to be done by team of at least 2 persons. Install the right KM600-CR jacket per drawing and pull the jackets tightly around the duct or equipment and fix it by Velcro tape.

- Wrap the jackets by the fastening tape with D-ring and Velcro Tape.

|

|

|

|